How To Use A HVLP Spray Gun – A Complete Guide

In the world of painting and decorating, the biggest frustrations often comes down to mastering the tools of the trade. In this guide, we’re going to talk about HVLP spray guns and how to set them up and how to get the best out of them. We will discuss:

- What a HVLP spray gun is

- The advantages of using a HVLP spray gun

- How to set up a HVLP spray gun

- How to use a HVLP spray gun

- Other important points to consider with HVLP spraying

- HVLP spray painting courses

What Is A HVLP Spray Gun?

HVLP stands for high-volume, low-pressure. A HVLP spray gun operates by using a high volume of air at low pressure, allowing for better control and a smoother finish compared to traditional spray guns. They produce a fine paint mist while minimising wet overspray and material waste. HVLP spray guns are considered to be more efficient and environmentally friendly because more paint is transferred to the surface being painted rather than dispersing into the atmosphere.

HVLP systems are available in several ‘stages’. The most commonly used HVLP spray guns are typically the three-stage HVLP and the five-stage HVLP. The stage refers to the fans that produce the pressure, with each stage adding around 2 psi (pounds per square inch). For a system to be classed as HVLP, it cannot be more than 10 psi. Therefore, the 5 stage is the most powerful HVLP system available in the uk, however there is a stage 6 now on the USA market from Apollo.

How Does A HVLP Spray Gun Work?

Traditional brushing and rolling can be time-consuming. The controlled, low-pressure spray from a HVLP system ensures an even and consistent coat of paint. Using air at a low pressure atomises the paint, creating a softer, more controlled spray pattern and a fine finish with minimal overspray. A HVLP spray gun typically has a maximum air pressure of 9.5 psi and can be better for certain applications, such as automotive painting, kitchen painting, furniture finishing, and industrial coatings.

Benefits Of Using A HVLP Spray Gun

In recent years, the HVLP sprayer has emerged as a game-changer in our industry, revolutionising how we, as decorators, can approach our projects, fast becoming one of the sprayers of choice for painting professionals. There are a number of reasons why using HVLP spray guns is so popular:

1. Efficiency and Speed

One of the standout advantages of an HVLP spray gun over brush and roller is its efficiency. These machines deliver a high volume of paint at a low pressure, allowing you to cover surfaces quickly and evenly. This means that decorators can complete projects in a fraction of the time it would take with traditional brushes and rollers. Airless spraying is another option that many decorators also use and that we encourage professionals to become proficient in..

2. Precision

Using a HVLP sprayer gives you exceptional precision and control. Whether you’re working on intricate details or large surfaces, the ability to adjust spray patterns with different sized needle sets ensures that you achieve the desired result with minimal overspray.

3. Flawless Finish

An HVLP sprayer produces a smooth, professional finish that’s hard to replicate using traditional methods. This is particularly important when working on kitchens, furniture, or other high-end projects where a quality finish is crucial and the customer wants the off-the-shelf look. There will always be a time and place for brush and roller, and we don’t want you to abandon them altogether, but if you want the best finish, brushes don’t come close to a HVLP spray gun.

4. Versatility

A HVLP sprayer is a versatile tool for various applications, including furniture, cabinetry, staircases and more. They are also very controllable, allowing you to adjust the fan width on the gun and dial it up to as much as 30 centimetres and down to as little as 1 centimetre. This is perfect for spraying things like stair spindles, where very little paint is wasted or oversprayed around the spindle. This flexibility makes a HVLP spray gun an invaluable addition to any decorator’s toolkit.

5. Cost Savings

While there may be an initial investment in an HVLP system, the reduced paint wastage and faster project completion will ultimately save you money in the long run.

6. Low Maintenance

HVLP systems are ideal for decorators because they’re small and portable, and easy to keep in your van and into a customer’s house. They can spray many types of paints that a decorator uses and are good at spraying solvent based or thinner products such as Zinsser BIN and Lacquers.

Another massive advantage is that the spray guns will last a long time if you look after them. The biggest problems we find with HVLP are when the gun is not cleaned properly. You need to strip it down and make sure everything is spotless before you put it back together. It won’t take long to take it apart and it will save you a lot of time and frustration in the long run. If you’re spraying a solvent based coating then clean the gun out with the appropriate thinner for the product or use acetone. Acetone is a crosslinker between oil/solvent and water meaning that it won’t react to either, and it won’t cause you problems or contamination when you spray. Once you know how to clean a HVLP spray gun, you can do it really quickly and be ready for your next job.

7. Interchangeability

One of the standout advantages of HVLP is interchangeability. Unlike traditional brushes and rollers, where each job may require a different tool, HVLP spray guns are much more adaptable. You can switch between guns, needle sets and even add a pressure pot to increase the paint quantities in the pot and allow you to adapt to various projects and surface types. With this, you can simplify your toolkit and save money.

What Equipment Is Used With A HVLP Spray Gun

A HVLP spray gun system is made up of three parts: the turbine, the hose and the gun.

The Turbine

The turbine draws air in from the outside and compresses it; there is no storage tank, so the compressed air is sent immediately down the hose to the gun. The size of the turbine will determine the pressure. A 5 stage turbine will produce around 9-10 psi, which is needed to spray decorative paints.

The Hose

This thick, inflexible hose is built to withstand the high volume of air that the turbine produces. The hose gets very hot near the turbine, so you need to be aware of this. Do not hold or touch the hose, especially the first metre of hose from the outlet. Because the hose is so stiff and inflexible, you’ll need to add a short, flexible ‘whip hose’ between the end of the hose and the gun.

The Gun

Guns are available in 3 types.

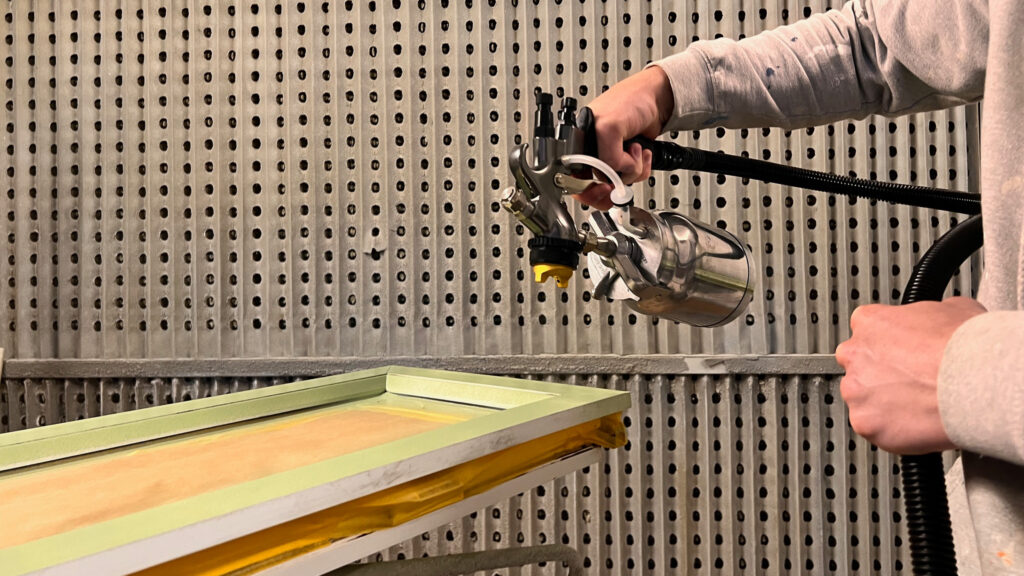

- Gravity feed – where the paint cup is on top of the gun. These are nicely balanced and are great if you’re working in a workshop or booth.

- Suction feed – with the paint cup below the gun, this makes the gun easier to put down onto a flat surface between spraying. These are better for onsite spraying.

- Pressure feed – this has a separate paint container called a pressure pot. The pressure pot holds more paint, typically 2 litres. There are 2 lines from the pressure pot to the gun, which feeds the gun with paint and air. This set-up means that the gun is light and can be turned to any angle when spraying.

How To Set Up A HVLP Spray Gun

Let’s get into the practical details of how to set up a HVLP spray gun. There are several key steps to follow to ensure optimal performance before you start spray painting:

1. Prepare Your Workspace

Before you begin, ensure that your workspace is well-ventilated and free from dust and debris. HVLP spraying is efficient, but it’s essential to maintain a clean environment for the best results. If you are on site then protection is key. Although wet overspray is minimal with HVLP, there is a lot of dry atomised paint and this will land on the surfaces you don’t want it to, so make sure you mask further than you think. This is one of the huge differences between airless and HVLP; airless produces more wet overspray which will dry on a surface, whereas HVLP produces more dry overspray that lands like dust.

2. Choose The Right Needle Set

Understanding the difference between needle sets in HVLP guns and how each helps you achieve the desired spray pattern and finish is an essential part of your set up. The primary distinction lies in the numbers on the needle and the nozzle.

- A 1.8 needle and nozzle set is designed to fit snugly and create a specific spray pattern. When you run your finger over it, you can feel the precision of the fit.

- In contrast, a 1.5 needle with a 1.8 nozzle creates a notably different pattern, with a significant gap when paired.

These numbers are your guides for selecting the appropriate needle and nozzle combination for your project. It’s important to note that both needle sets can produce excellent outcomes, but the choice depends on your specific project requirements. Understanding these differences empowers decorators to select the correct needle set for each task, ensuring precise and consistent results. Use a 1.5 needle and nozzle for things like kitchen or furniture paints and then 1.8 for things like spray granite or stoneflecks as the products are thicker and more grainy.

3. Test With Water First

Always test your HVLP spray gun with water before using paint. This helps you check for any blockages and ensures that the gun is functioning correctly. Water is easier to clean up in case of issues.

4. Adjust the Fluid Flow

Gradually pull back the fluid adjustment knob until you achieve a satisfactory finish. You may need to thin the paint slightly to achieve the desired atomisation and fan pattern.

5. Thin Your Paint (If Necessary)

To thin your paint effectively with an HVLP gun, take a rag and gradually drip in small amounts of water (or correct thinners if using solvent based paint). This controlled method ensures that you achieve the right consistency without over-thinning the paint. Just a side note and one from experience; not all paints can be sprayed through HVLP. If you have to thin the paint a lot to get it to spray nicely then don’t use HVLP as you are losing the properties of the paint by over thinning. Consider compressor, airless or just revert back to traditional methods instead.

6. Adjust The Settings

One of the great things about a HVLP system is that the turbine doesn’t need any setting up; you just switch it on, and you’re spraying. The gun can be a little trickier. There are 2 controls on the gun, one that controls the fan width and one that controls the paint flow. You need to set the fan to the desired setting, say a 4-inch fan, and then turn the fluid flow up to match the fan setting.

How To Use A HVLP Spray Gun

With your HVLP spray gun set up and paint thinned to perfection, it’s time to start spraying. Here are some tips on how to use a HVLP gun effectively:

- Maintain a consistent distance from the surface you’re painting to ensure even coverage

- Overlap each pass slightly to prevent streaks and achieve a uniform finish

- Keep the gun moving at a steady pace to avoid paint build-up in one spot

- Practice on a test surface before tackling your main project to get a feel for the gun’s performance

Spraying furniture with an HVLP sprayer often feels like an artistic performance. As you pull the trigger and release a fine mist of paint, there’s a sense of control and precision that’s truly captivating. It differs from brush painting and can be much more fun than rolling. Spray painting is like wielding a magic wand that transforms dull surfaces into vibrant, beautifully coated pieces.

To achieve this, you must practise and experiment with different spray patterns and techniques. Create gradients, fades, or find ways to infuse your personal touch into your work. Not practising and getting it wrong can be highly frustrating. Preparing and training makes the difference. To perfect your skills, you could consider enrolling on an airless paint spraying course.

Can I Spray the Same Paint Through HVLP and Airless?

While knowing how to use a HVLP spray gun correctly is the number one priority, you also need to understand which paint to use with your gun. It’s natural to wonder whether you can use the same paint with both HVLP and airless spray systems: the short answer is yes, you can!

Whether you’re working on a project that requires the precision and finesse of HVLP or the speed and power of airless spraying, your chosen paint can accommodate both methods.

However, it’s essential to recognise the fundamental difference between these two systems when it comes to paint application.

- Airless Spray: Airless spray systems work by pressurising the paint and forcing it through a tiny nozzle, creating a high-speed stream of paint particles. This results in a powerful and efficient application. Airless systems can handle a wide range of paints, including thicker materials, and typically operate at much higher pressure, often up to 2,000 psi.

- HVLP Spray: HVLP, on the other hand, uses air at a lower pressure to atomise the paint, creating a softer, more controlled spray pattern. HVLP systems are known for their ability to deliver a fine finish with minimal overspray. However, they are limited in terms of pressure – usually, a HVLP spray gun is limited to around 9.5 psi.

With airless spraying, you have the flexibility to increase pressure to accommodate thicker paints. In contrast, HVLP machines are fixed at a lower pressure, and this is where some adjustments may be necessary.

If you plan to use the same paint with both HVLP and airless systems, you might need to thin the paint for HVLP spraying. While there’s no one-size-fits-all formula for thinning, it’s a straightforward process, as we mentioned above.

5 HVLP Spray Gun Tips

Now that we’ve covered how to set up a HVLP spray gun and how to use a HVLP spray gun, here are some simple tips that can make it easier and more efficient:

- Buy a 5 stage turbine. The most common mistake that decorators make is buying a turbine that isn’t powerful enough.

- Get a 1.5mm tip set. Most HVLP systems will come with a mid-range tip size, but it’s worth checking before ordering. This size is a good all-rounder.

- Get a whip hose. This is essential for comfortable spraying because the main hose is so stiff and inflexible. Most new HVLP machines come with a whip hose but check before you buy.

- Clean the gun thoroughly after each use. Most problems you will encounter when spraying with HVLP are due to the gun not being cleaned properly. It is worth taking the tip and needle out once you’ve cleaned the gun to make sure that these are also spotless.

- Make sure that the paint is not too thick. HVLP sprayers prefer thin paint. If you’re spraying a paint that’s been designed to be sprayed, then it will be fine, but if you’re spraying something that’s designed to be rolled, you may need to thin it before it sprays or find a better alternative.

Expanding Your Skillset with City & Guilds Assured Training

If you’re intrigued by the potential of HVLP spraying, our City & Guilds Assured course is designed for decorators like you. In this comprehensive programme, you’ll dive deep into the world of HVLP and compressor set-ups and gain practical experience with various guns and accessories.

During the course, you’ll have the opportunity to practise spraying on a variety of surfaces, from doors and spindles to fireplaces and chairs to test your skills. This hands-on training will sharpen your skills and boost your confidence in delivering top-notch finishes using HVLP equipment.

Learning how to spray with a HVLP sprayer is a valuable skill that can elevate the quality of your work and increase your efficiency as a decorator. At our training academy, we train and empower decorators to harness the potential of HVLP technology and integrate it into their businesses for increased profitability. Open up your opportunities, embrace the efficiency, enjoy the transformation, and make HVLP your trusted partner in creating exceptional finishes.

Download Now – Find Out How To Access Funding For Training – Get £5,000 Free Funding [FREE DOWNLOAD]